Custom Screwdriver#

Buy Custom ScrewdriverHow the screwdriver works#

A custom screwdriver is needed to turn the screws during construction and for later adjustment. Adjusting electrodes is a slightly delicate process, having the right tool for the job makes it much easier. There are two issues with the process: 1) Good depth tracking requires very precise adjustment, so that as errors accumulate, they don’t become significant. 2) Electrodes and springs should not be touched.

This custom screwdriver for half-circle/ half-moon screw heads makes adjustments much easier by breaking the step of getting the screwdriver onto the screw head into two steps:

Roughly engage screw driver with screw head, correct rotation doesn’t matter in this step.

Gently rotate the screwdriver until it engages with the screw head and is locked into the same angle as the screw. It will slip a bit (~1mm) further onto the screw when it engages. Now you can apply more torque to rotate the screw.

Building the screwdriver#

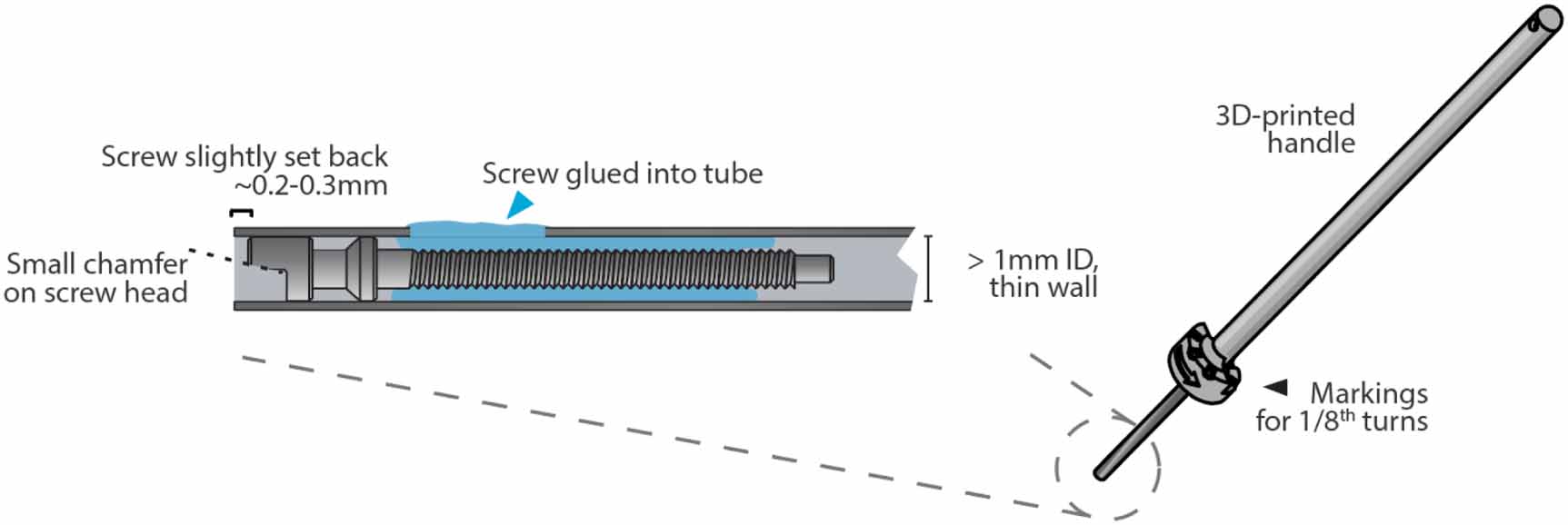

Such screwdrivers can be made by gluing or soldering a screw into the end of a piece of steel tube with an ID of close to 1 mm. Thin-walled tubes are recommended because thicker tubes will interfere with the rest of the drive body when adjusting. The screw used for this should be inspected to make sure that the protruding half-moon section is on the smaller side, so it can interface with other screws. It can also help to carefully bevel the edge of this section with fine sandpaper. The screw should be slightly recessed into the steel tube so that the screwdriver can be locked onto a screw axially first, and then rotated to snap into the mating screw rotationally. A 3D-printed screwdriver handle and detailed tube measurements and sources are available on the git repository.

Assembled or unassembled screwdrivers can be bought in the Open Ephys store.

A handle can be made by applying heat-shrink tubing to the cannula, or by 3D printing the handle from files available on the git repository.