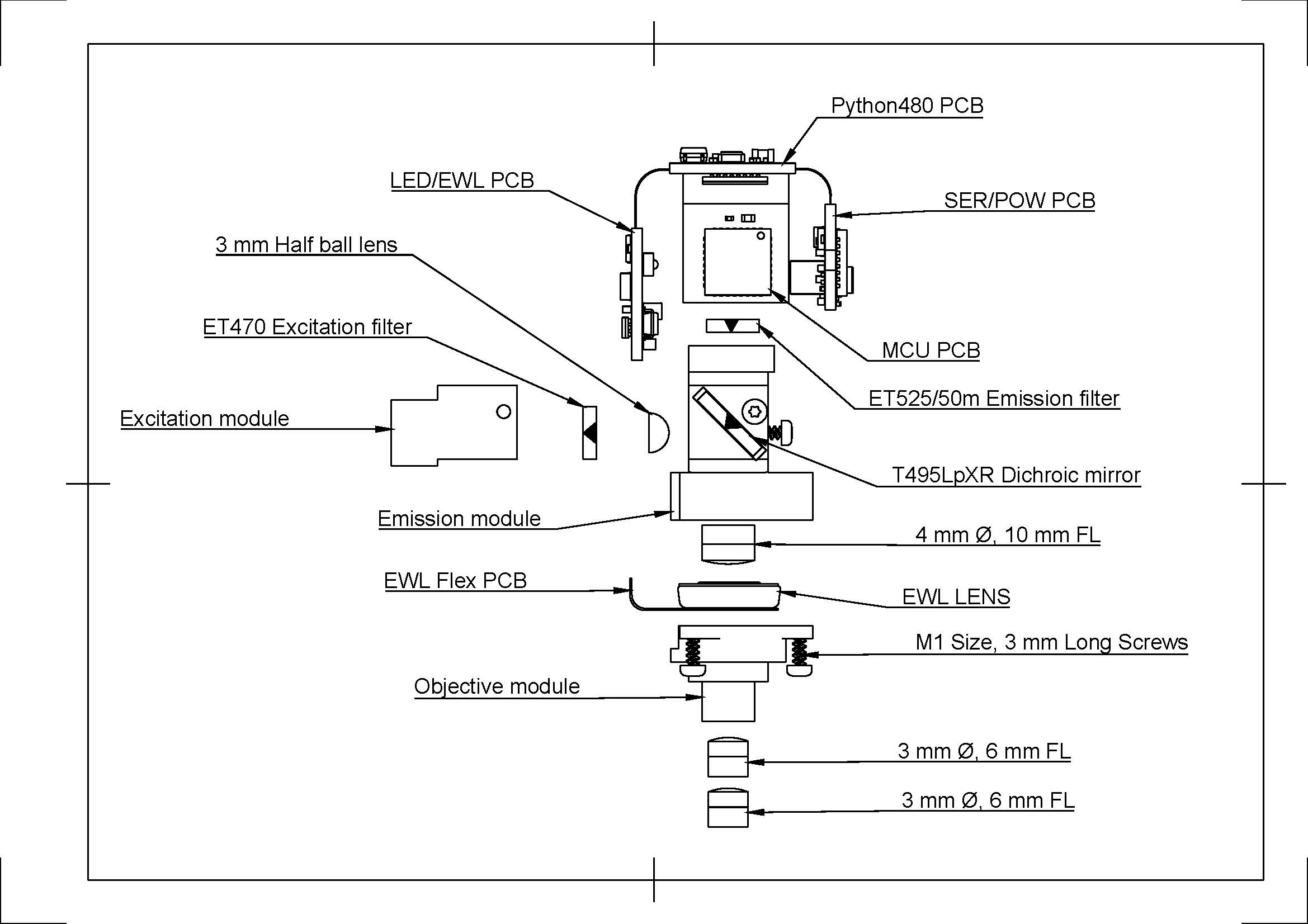

Assembling the UCLA Miniscope V4#

This assembly guide is specific to the UCLA Miniscope V4.4 supplied by the Open Ephys Store and is provided on an “as-is” basis, you are always responsible for your own decisions regarding assembly and experiments.

Necessary Equipment for Miniscope Assembly#

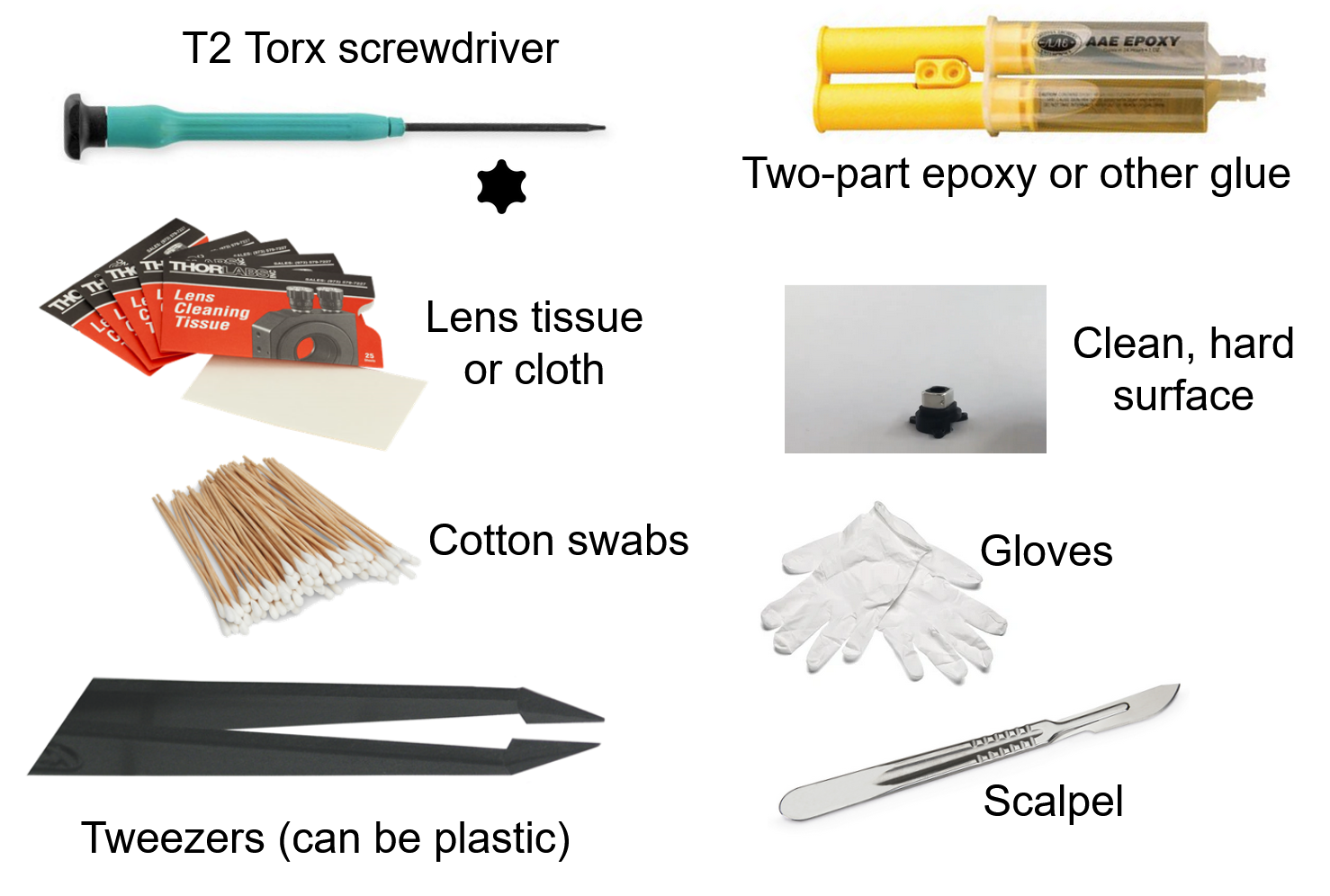

It is recommended to have this equipment for assembling and servicing the UCLA Miniscope v4:

ESD gloves (to safely handle the PCB and maintain cleanliness of optics)

Lens cloth or lens tissue (to maintain cleanliness of optics)

Compressed air spray (to maintain cleanliness of optics)

Fine tweezers/forceps

Torx T2 screwdriver

Scalpel/biopsy punch

Adhesive (Overview of adhesive for UCLA Miniscope v4 assembly)

Data acquisition hardware (e.g. Miniscope-DAQ) and tether

Below is a visualization of the equipment that can be used to assemble and service the UCLA Miniscope v4:

Assembly Steps#

1. Prepare#

Check all parts for any Delrin burrs sticking out. Scrape them off with a biopsy punch or tweezers.

2. Objective Module#

Stand one of the 3mm ⌀ 6mm FL lenses on a flat surface. Make sure the lens is standing on its flat side - it should not wobble.

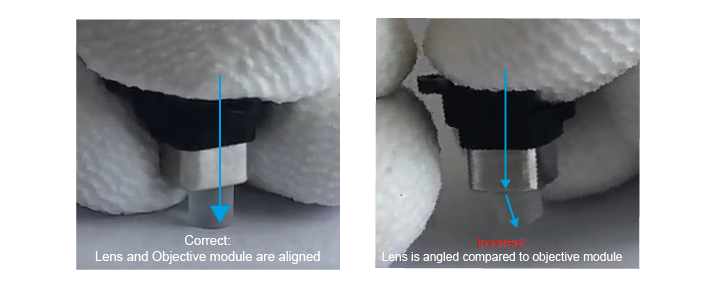

Place the objective module directly over the lens and push down. Make sure that you are pushing in a straight line onto the lens, as any angle can cause chipping. You may have to use some force to do this, if the objective module is a bit tight (you can hear in the video that it makes a sound). Downward force is ok as long as the lens and objective module are completely aligned. If you see the lens stick out at an angle, remove it and reposition it.

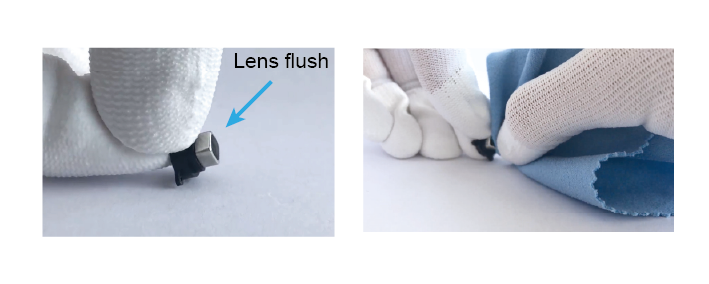

Make sure the lens is completely flush with the body and does not stick out.

Once the lens is flush with the edge of the objective module, clean the edge of the lens with a soft cloth.

Important

Sometimes extra burrs come off due to the first lens. If they are not removed before inserting the second lens, they can become trapped between the two, which interferes with your image and is difficult to remove. To prevent this problem, inspect the module for small Delrin burrs once more. If they are already loose, you can tap the module gently to allow them to fall out. Otherwise, you can scrape them off using forceps. Be careful not to scratch the lens.

Then, repeat this with the second 3mm ⌀ 6 mm FL lens, again making sure that the lens is standing on its flat edge. Push the objective module down until the second lens is flush with the edge of the objective module.

3. Excitation Module#

Caution

Take great care not to scratch the filter, this will damage the coat that actually performs the filtering and will allow unwanted wavelengths to pass through the filter.

Locate the arrow on your 470nm excitation filter. This arrow must point towards the light source, in this case towards the LED on the Miniscope PCB.

Press the filter, arrow pointing down, into the excitation module. If it does not fit easily, use a scalpel or biopsy punch to scrape out a small layer of the inner edges of the Delrin on the excitation module to allow the filter to click in.

4. Emission Module#

First, screw a self-threading screw into the hole on the side of the body, then remove the screw again. This is so that you can remove any small burrs that are generated by the self-threading screw, while the body is still disassembled and therefore easier to clean. Hold the emission module up-side down and tap to get these burrs out of the body. You can spray compressed air through the module to make sure it is clean.

Find your 4mm ⌀ 10mm FL lens. This one has only a very slight curve at one edge, and should be placed with the curved edge down (in contrast to the objective module lenses). Stand the lens on a flat surface, with the curved edge down. If you press it, it should wobble.

Press the emission module down on top of this lens.

Once it is secure, you can turn the module upside down and, using a cloth on top of the lens, press to ensure the lens is as flush with the module as possible.

Next, place the dichroic filter in the slot on the side of the emission module. The arrow must be facing downwards, towards the 4mm ⌀ lens.

Look through the top of the module to check that there are no burrs or pieces of visible dust in the scope so far.

If it looks clean, place the half-ball lens in the round pocket on the side of the body. Secure it in place by attaching the excitation module using two screws.

5. Assembly#

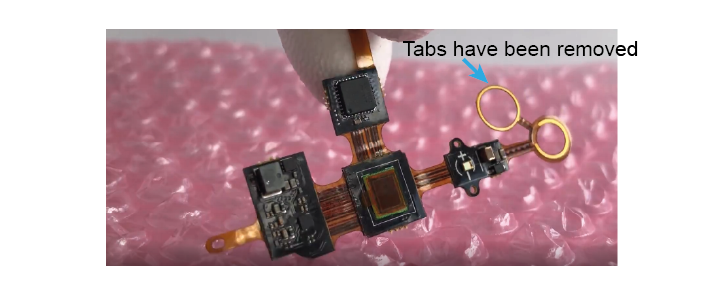

Cut the extra tabs from the electrowetting lens PCB.

Screw the PCB to the excitation module using the two holes.

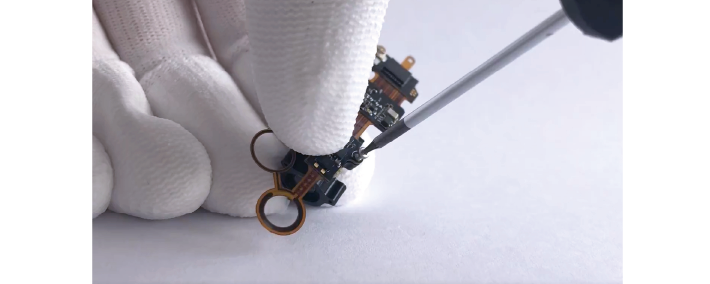

Carefully pre-bend the two circles in the PCB (do not press too hard, just gently shape them).

You can now put an EWL in between these circles and attach the objective module to the emission module. Check that the EWL is in the correct orientation.

Finally, use compressed air to clean out the sides of the pocket at the top of the scope. Make sure it is very clean, as any pieces that come loose here later on, will fall directly on your sensor and interfere with your imaging. Place the 525 nm filter in the pocket, with the arrow pointing down.

Remove the protective film from the PCB and close the sensor over the top of the scope. You will probably have to hold the PCB in place while you do a first test of the scope.

6. Test before securing#

Connect your Miniscope to a computer using a DAQ and a coaxial cable. Check that:

The EWL allows you to focus electronically.

The LED responds to you increasing/decreasing the value.

There are no visible specks on the image. It is worth moving the scope around a little to make sure there are no debris in the corners of the 525 pocket that can fall into view.

If the scope passes these tests, you can glue the PCB to the emission module. With the scope held in a vice, apply 5-min epoxy using a toothpick and leave to dry.

Once the epoxy is fully dry, screw in the PCB flaps.

Test the scope one final time, and you are ready to image!

Troubleshooting Assembly#

1) When I change the focus setting, the image does not change.#

This is almost always due to the PCB being incorrectly placed around the electrowetting lens and therefore not making full contact. Take a look at your objective module- do the screws need tightening so that the PCB and the lens are pushed closer together? Can you see any PCB stick out at the side? The circles of the PCB must fit neatly inside the objective module and touch the electrowetting lens.

2) There are marks on my image#

Dust and other debris can make their way into the scope at various positions. If the mark on your image is in focus, it is most likely a mark on the CMOS sensor of the PCB or the 525 filter. Clean both with a soft optics-safe cloth and test the image again. If the mark is large, see-through and out-of-focus, it could be dust on the lenses or the 495 dichroic. You will have to disassemble the scope to find the culprit, using compressed air to clean out places that are difficult to access. You want the center of your image to be very clean, however some dust/dirt can be inevitable, and users often reach a point where cleaning the scope more just introduces new marks. As long as marks are small and not in the center of the image, they should not greatly affect your imaging, but this depends on the application and is up to you to decide.

3) My scope looked clean, but now I see dark, in-focus marks/hairs#

These are often Delrin burrs that have come loose in the 525 pocket. The only solution is to unscrew the PCB flaps and remove the epoxy so that you can clean the sensor again. The easiest way to remove the epoxy is to very gently twist the Miniscope relative to the PCB to loosen the epoxy, the PCB should come loose. You can then remove the remaining epoxy with forceps so that you are free to reattach the PCB after cleaning.

Disassembly for PCB Replacement#

1. Remove the objective module#

Unscrew the three screws on the PCB flaps holding the objective module.

While unscrewing, press down gently on the module to prevent it from falling. A falling module can cause scratches or damage to the lens. Carefully set aside the objective module and the EWL lens, which will now be loose.

Keep the screws in a safe place for later assembly.

2. Detach the PCB from the excitation Module#

Unscrew the PCB from the excitation module by unscrewing the two screws that hold the PCB and the excitation module together.

Again, keep the screws secure for later assembly.

3. Remove the PCB from the scope#

Carefully snap the epoxy bridges connecting the PCB to the scope body using your fingers. Apply controlled, localized force to lever the PCB and break the epoxy bridges. Be cautious as the epoxy snaps to prevent components from flying out of the scope.

If the 525 nm emission filter comes out when removing the PCB from the scope, you should place it back into the emission module according to step 5.e in the Assembly Guide.

4. Replace the PCB#

To finish the PCB replacement, place the new replacement PCB, the EWL lens and the objective module according to the Assembly Guide steps 5.b to 6.c.